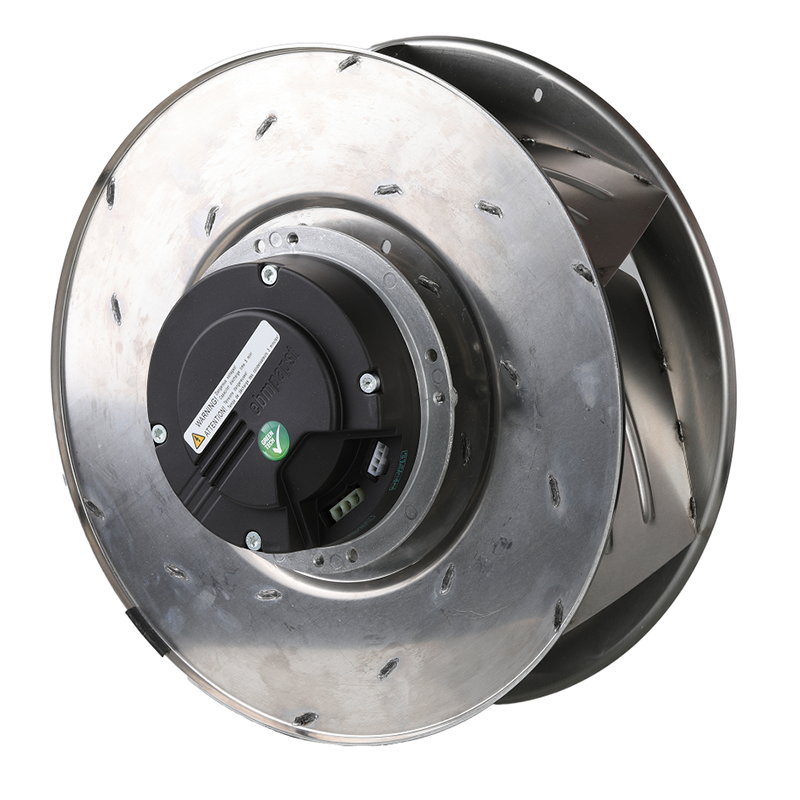

EC centrifugal fan -R3G355-AM14-61

Product Drawing

Introducing

The R3G355-AM14-61 is classified as a backward-curved, single-inlet fan, which guarantees the minimization of noise and maximization of efficiency. The unique blade design of the backward-curved impeller provides a smooth flow with no turbulence and allows for a higher static pressure. This configuration makes this fan an ideal choice for dust collectors, air filters, heat exchangers, and other industrial applications.

This EC centrifugal fan is equipped with the latest brushless DC motor that delivers high efficiency, low noise, and smooth speed control. The electronically commutated motor technology of this fan ensures a quiet performance, which makes it perfect for spaces where noise levels require to be kept to a minimum. The motor design also guarantees a longer lifespan, providing significant energy savings that can generate a fast return on investment.

The R3G355-AM14-61 is a single-inlet centrifugal fan, which means that it is designed to draw in air from one side and discharge it from the other side, allowing for a more straightforward and efficient installation. Additionally, its compact design and easy-to-access control drive panel also make it easy to install, operate, and maintain, even in limited spaces.

This centrifugal fan is made of high-quality materials that comply with international standards. It is designed for heavy-duty applications that require continuous operation, capable of handling high air volumes and pressures. The R3G355-AM14-61 is an excellent product for anyone who values efficiency, durability, and low maintenance costs.

In conclusion, the EC centrifugal fan, R3G355-AM14-61, is a high-quality, reliable, and cost-effective solution for your ventilation needs. Its unique backward-curved, single-inlet design with the latest EC motor technology ensures minimum noise level and maximizes energy savings. Invest in this centrifugal fan and experience superior air performance, longer lifespan, and low maintenance costs.

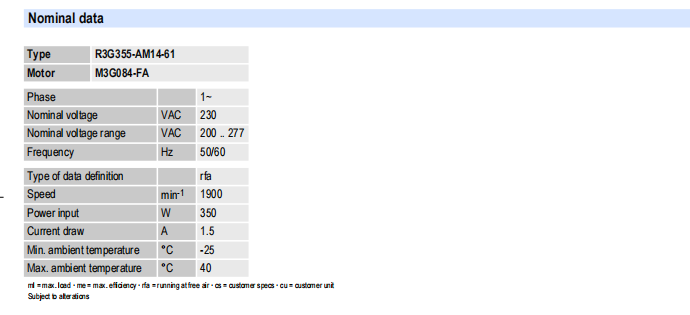

What’s the maximum voltage you can apply to a blower?

The maximum voltage that can be applied to a fan motor varies from model to model, but is typically 5%-10% above the nominal voltage listed. Consult the factory to determine the maximum voltage for a particular part number, and to learn more about the negative effects that high voltages might have on the motor

What is a fan’s of voltage range?

Ebmpapst EC fans are able to perform equally well across a range of input voltages. These fans will have the maximum and minimum acceptable voltages listed on the label, such as the one below:

Note that in order to reach a desired performance point, the fan may need to draw additional current at low voltages.

Can all 60 Hz blower motors operate on a frequency of 50 Hz?

Not all ebmpapst fans are designed to operate at both 50 and 60 Hz. If a fan is able to accept both 50 Hz and 60 Hz power supplies, it will have a “50/60Hz” mark on its label, such as the one below:

Consult the factory if you intend to use a power supply with a frequency that does not match the recommended frequency of your fan.

When determining fan performance, several factors are taken into consideration. These factors primarily include: airflow, static pressure, operating points, RPM, power & current, and sound performance. Of these factors, ebmpapst presents a performance curve with our products to provide a quick-glance overview of the performance. Performance curves use just three of the aforementioned factors: airflow, static pressure, and operating points.

What is Airflow?

For the air-moving industry, it is important to know how quickly some volume of air is being displaced from one location to another, or, more simply stated, how much air is being moved in a set amount of time.

Ebmpapst typically expresses airflow in Cubic Feet per Minute (CFM) or cubic meters per hour (m3/h).

What is Static Pressure?

Once again the air-moving industry is faced with another challenge, the resistance to flow. Static pressure, sometimes referred to as back pressure or system resistance, is a continuous force on the air (or gas) due to the resistance to flow. These resistances to flow can come from sources such as static air, turbulence and impedances within the system like filters or grills. A higher static pressure will cause a lower airflow, in the same way that a smaller pipe reduces the amount of water that can flow through it.

Ebmpapst typically expresses static pressure in inches water gauge (in. W.G.) or Pascals (Pa).

What is the System Operating Point?

For any fan we can determine how much air it is able to move in a given amount of time (airflow) and how much static pressure it can overcome. For any given system, we can determine the amount of static pressure it will create at any given airflow.

Taking these known values for airflow and static pressure, we can plot them on a two-dimensional chart. The operating point is the point at which the fan performance curve and the system resistance curve intersect. In real terms, it is the amount of airflow a given fan can move through a given system.

How do I read an air performance curve?

To aid in fan selection, ebmpapst provides an air performance graph with its products. The air performance graph consists of a series of curves that chart airflow against static pressure.

Follow along on the chart below. The x-axis is for airflow, while the y-axis is for static pressure. The blue line ‘A’ illustrates the fan’s performance outside of a system. To find the operating point 900CFM @ 2 in.w.g., follow the x-axis to 900, then follow the y-axis up to 2 (Point ‘B’). Since this operating point ‘B’ is below the performance curve, it is a point that the fan can achieve.

Lines ‘C’, ‘D’, and ‘E’ are example system resistance curves – as airflow increases, the static pressure (or resistance to airflow) also increases, making it harder to move air. Typically, any point between the highest and lowest of our example resistance curves is the ideal operating range for the fan to achieve its highest efficiency. Some performance graphs will have multiple airflow curves; this would indicate that the fan is capable of multiple speeds in order to match operating points below its maximum speed, thus saving energy.

Forward Curved Impellers

- There are two types of forward curved impellers, dual and single inlet.

- Used primarily in medium pressure, high flow applications.

- Possible market uses: ventilation, refrigeration etc.

Backward Curved Impellers

- Used primarily in high pressure, high flow applications.

- Possible market uses: data center, general ventilation, agriculture; transportation etc.

Axial Fans

- Used primarily in low pressure, high flow applications.

- Possible market uses: LED, ventilation, agriculture; transportation, etc.